Add to Cart

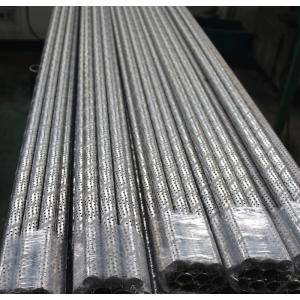

201 304 Spiral Perforated Steel Pipe Galvanized For Low Carbon Plain Steel Sheet

This type of perforated tubing is made of high quality low carbon plain steel sheet after being perforated on the digital control perforated machines. It you don't see what you are looking for, we can custom punch many patterns.

Forward filter is good at producing spiral welded steel perforated pipe, we started this business ten years ago.

Spiral perforated pipe is welded by perforated steel roll which is revolving on the production line, different with straight perforated pipe. Welding ling is longer, so it can endure 30% more pressure.

Normally spiral welded steel is made of stainless steel like 201, 304, 316 which is used in petrol or textile, but it can also used in filtration, better than straight welded perforated pipe. In some situation it can also use galvanized steel or carbon steel. In this case we need minimum order quantity.

Different application need different steel like carbon steel, stainless steel, galvanized steel.

Perforation pattern usually is round holes, there is straight line holes and staggered line holes, different open area need different diameter center distance. 15%-33% open area is common configuration. Formulas for your reference

A: 60° perforation pattern or staggered pattern: hole diameter * hole diameter*90.69% / hole center distance * hole center distance

B: 180° perforation pattern or straight pattern: hole diameter * hole diameter * 78.5% / horizontal diameter center distance * vertical diameter center distance

C: Other special cases as follows

Spiral Welded Steel Perforated Pipe High Quality with Attractive Price is offered by Forward Filter, when become our important customer with good quantity business, special quotation is available.